-

Korea.net's 24-hour YouTube channel

Korea.net's 24-hour YouTube channel- NEWS FOCUS

- ABOUT KOREA

- EVENTS

- RESOURCES

- GOVERNMENT

- ABOUT US

View this article in another language

- 한국어

- English

- 日本語

- 中文

- العربية

- Español

- Français

- Deutsch

- Pусский

- Tiếng Việt

- Indonesian

A team of researchers has recently developed an environmentally friendly way to generate thermal power using oxygen. The technology is currently in the international spotlight since it is considered highly-effective and environmentally friendly, saving costs in both development and production.

Thermal power generation accounts for approximately 60 percent of the world’s total power generation thanks to its merits of having well-built infrastructure and having low generation costs. Weakness remain, however, as it causes some environmental pollution, such as emitting greenhouse gases. For this reason, the world has been focusing on developing an environmentally friendly thermal power generation technology using oxygen, such as the integrated coal-gasification combined-cycle power system (IGOC) and Oxyfuel technologies. These technologies require a massive oxygen supply and measures to reduce production costs.

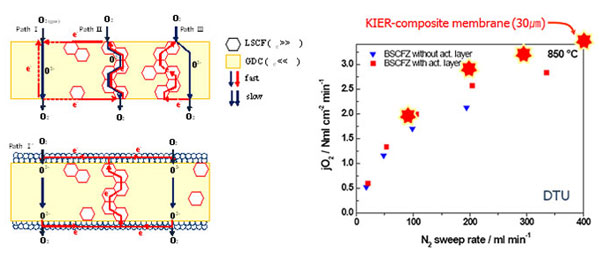

The research team, led by Dr. Yu Ji Haeng at the Korea Institute of Energy Research (KIER), recently developed a new oxygen membrane technology that uses a cerium oxide complex which can stably transport an oxygen ion. The team developed the membrane with a thickness of only 30 micrometers by using a less-expensive material made from cerium oxide complex and perovskite, a metallic oxide that has high conductivity.

By using the new oxygen membrane, the new technology can save up to 48 percent of the costs of separating the oxygen and 68 percent of the costs of producing the oxygen. This process is also up to ten times more chemically stable when compared to existing ceramic oxygen membranes, one of the highest levels in the world.

In the past, cryogenic separation was used to separate oxygen in the air by using the difference in boiling points. However, it required large-scale plants and required a lot of electricity to compress the air.

Dr. Yu said, “This technology can be applied to generation power plants or to the steel industry to boot effectiveness. It is so far the latest technology with the highest performance in terms of oxygen penetration, and it will dominate the oxygen membrane market in the near future.”

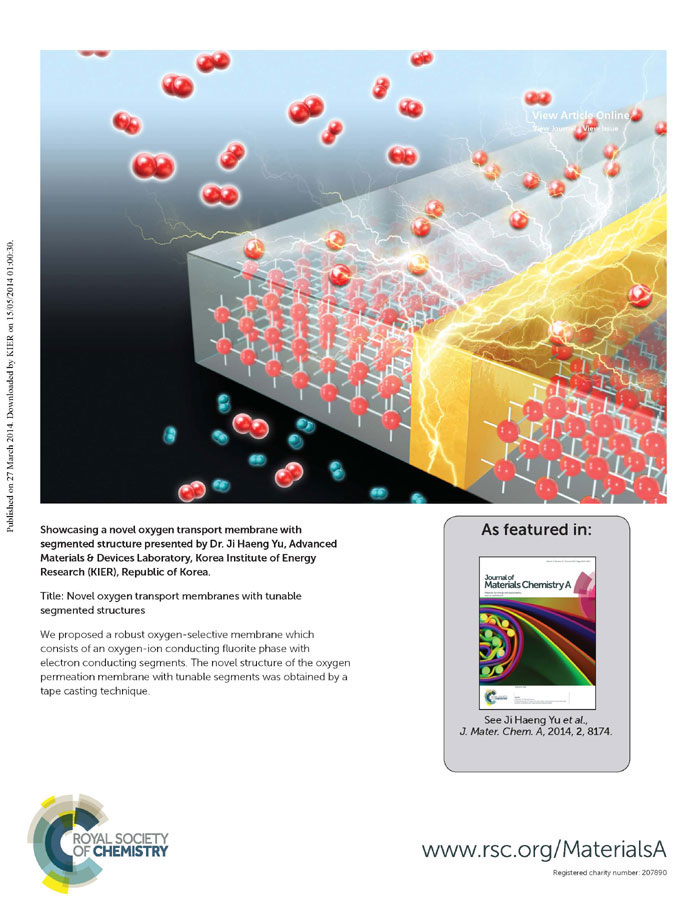

The research results were published this past February in the Journal of Materials Chemistry, published by the Royal Society of Chemistry, and in the Chemistry of Materials.

By Yoon Sojung

Korea.net Staff Writer

arete@korea.kr

Thermal power generation accounts for approximately 60 percent of the world’s total power generation thanks to its merits of having well-built infrastructure and having low generation costs. Weakness remain, however, as it causes some environmental pollution, such as emitting greenhouse gases. For this reason, the world has been focusing on developing an environmentally friendly thermal power generation technology using oxygen, such as the integrated coal-gasification combined-cycle power system (IGOC) and Oxyfuel technologies. These technologies require a massive oxygen supply and measures to reduce production costs.

The research team, led by Dr. Yu Ji Haeng at the Korea Institute of Energy Research (KIER), recently developed a new oxygen membrane technology that uses a cerium oxide complex which can stably transport an oxygen ion. The team developed the membrane with a thickness of only 30 micrometers by using a less-expensive material made from cerium oxide complex and perovskite, a metallic oxide that has high conductivity.

By using the new oxygen membrane, the new technology can save up to 48 percent of the costs of separating the oxygen and 68 percent of the costs of producing the oxygen. This process is also up to ten times more chemically stable when compared to existing ceramic oxygen membranes, one of the highest levels in the world.

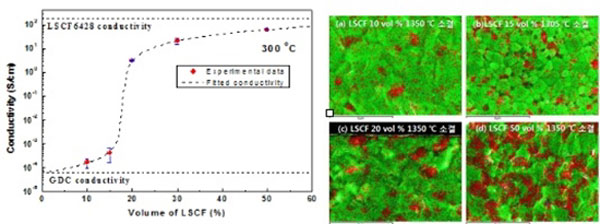

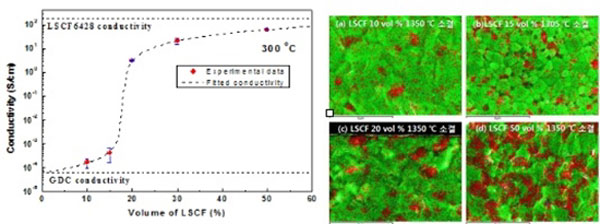

The conductivity and microstructure of the oxygen membrane.

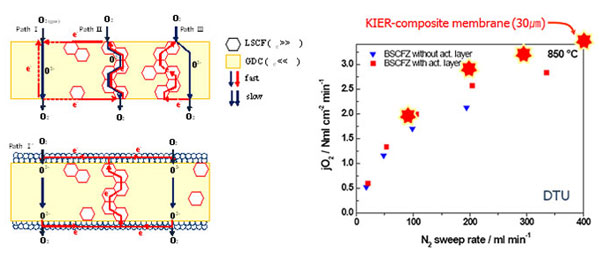

A comparison between oxygen penetration rates of the newly developed oxygen membrane (red dots) and existing oxygen membranes (blue dots).

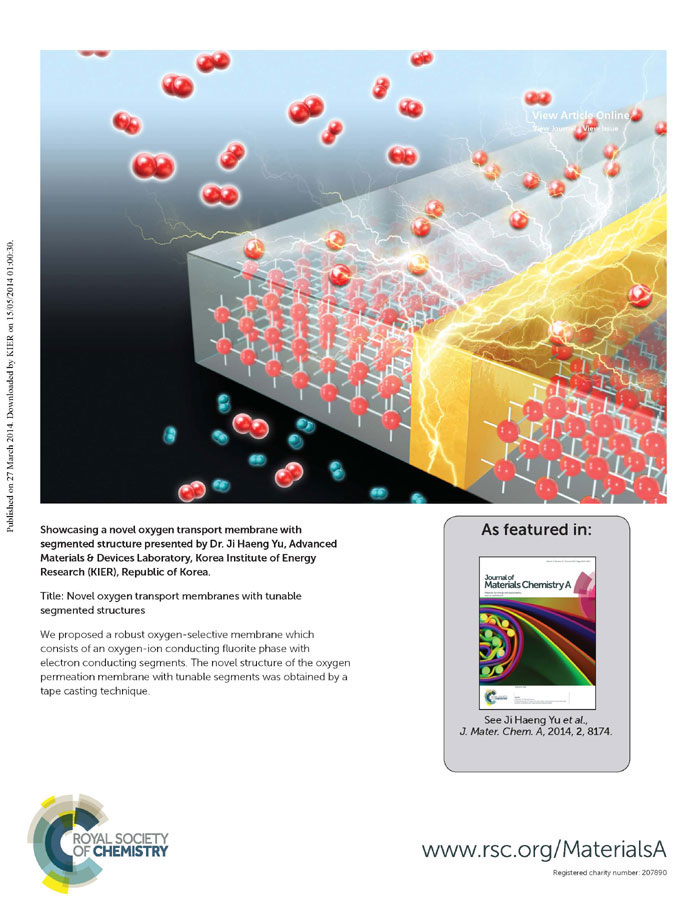

Dr Yu Ji Haeng of the KIER led the research.

In the past, cryogenic separation was used to separate oxygen in the air by using the difference in boiling points. However, it required large-scale plants and required a lot of electricity to compress the air.

Dr. Yu said, “This technology can be applied to generation power plants or to the steel industry to boot effectiveness. It is so far the latest technology with the highest performance in terms of oxygen penetration, and it will dominate the oxygen membrane market in the near future.”

The research results were published this past February in the Journal of Materials Chemistry, published by the Royal Society of Chemistry, and in the Chemistry of Materials.

The results of the team's research were published in the Journal of Materials Chemistry, published by the Royal Society of Chemistry.

By Yoon Sojung

Korea.net Staff Writer

arete@korea.kr

Most popular

- China warmly welcomes first Korea-born giant panda Fu Bao

- First hearing-impaired K-pop act hopes for 'barrier-free world'

- Novelist Hwang's 'Mater 2-10' shortlisted for Int'l Booker Prize

- Expats could account for 7% of population in 20 years: report

- Nat'l Fire Agency picks 137 elite staff for deployment abroad