This is the high-temperature, high-pressure sintering machine in December 2023 at New Materials Center of Gangwon Technopark in Gangneung, Gangwon-do Province. The device reduces porosity and enhances the strength and durability of ceramic and composite materials at high temperatures and pressure.

By Charles Audouin

The technopark program, which has been designated and run by the government since 1997, is the key foundation for driving the technological innovation and economic stimulation of provincial industries.

Serving as a focal point of such advancement, the country's 19 technoparks back each region's strategic industries through corporate support and formation of research networks between academia and industry.

Gangwon Technopark exemplifies the transformation of Gangwon-do Province's geographical trait of fragmented industrial structure into opportunities.

Since its launch in 2003, the high-tech complex has cultivated a Gangwon-do-type industrial cluster by integrating specialized sectors like bio and health, antibody pharmaceuticals in Hongcheon-gun County, digital health care in Wonju, liquefied hydrogen in Samcheok and coal waste resources in Taebaek.

The provincial capital of Gangneung has emerged as a hub of the cutting-edge supply chain in new ceramic materials. Gangneung Science Industrial Complex has about 70 equipment used in this sector.

Ceramics are inorganic materials made by combining metals and non-metals and hardening them at high temperatures. Their resistance to high heat and insulation make them useful in a range of sectors like electrical, mechanical, chemical and biomedical as well as in core components of semiconductor equipment and high-performance substrates.

The Ceramic Business Support Center, which opened in December last year, develops materials and components that leverage ceramic properties. The place is equipped with three leased factories, pilot production lab, and equipment like hot isostatic pressing machine and high-temperature and pressure sintering machine to aid businesses from research to output.

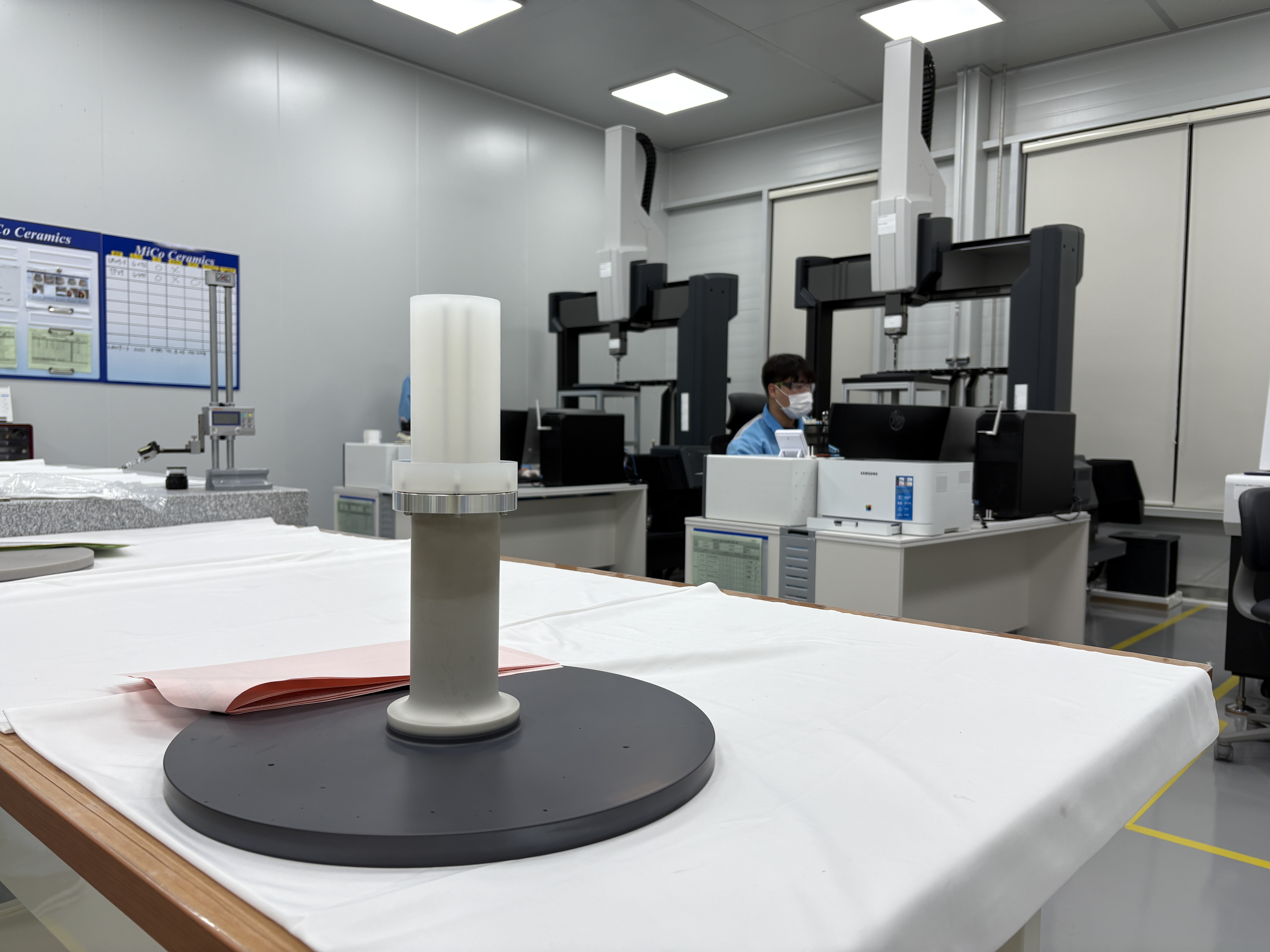

A staff member of MiCo Ceramics on Nov. 6 measures the size of the component of an aluminum nitride heater used in semiconductor equipment at the quality inspection room of the company's No. 4 plant in Gangneung, Gangwon-do Province. A precise dimensional check is crucial for verifying if the material meets design standards.

A company that has aggressively utilized this foundation is MiCo Ceramics, a manufacturer of ceramic components for semiconductors.

MiCo received customized support from Gangwon Technopark to set up four plants in Gangneung. Some 220 of its 600 staff work at the factories to make key components such as ceramic heaters and electrostatic chucks.

"We chose Gangneung for its well-built infrastructure for ceramic industry research and development and stable electricity supply," a source at the company's heater production team said. "Along with the growth of artificial intelligence chips, our company will also continue to grow."

Another Gangwon Technopark success story is Hassbio, a maker of materials for dental ceramic prosthetics. Since moving into a venture plant in 2009, it has slashed development costs and boosted competitiveness by borrowing equipment and using research infrastructure.

Hassbio was listed last year on the secondary stock market KOSDAQ and exports its products to 75 countries.

The Gangwon-do government plans to use this trend as a stepping stone to complete a "K-semiconductor cluster" by 2033.

Chuncheon will get a joint chip research center and university and Wonju the Korea Semiconductor Training Institute. Thus Gangneung will serve as a key production base for ceramic semiconductor materials and parts.

caudouin@korea.kr

![[Innovative Gangwon-do] ① Chuncheon zone leads bio advances](/upload/content/image/662c64dd0b1b4b03bff18efacde9eba6_20251117104627.jpg)