View this article in another language

- 한국어

- English

- 日本語

- 中文

- العربية

- Español

- Français

- Deutsch

- Pусский

- Tiếng Việt

- Indonesian

*This is the fourth part in our series, “Gat, traditional headgear in Korea.”

3. The process and tools of making a gat

1) Materials and supplies used in gat-making

2) Finishing work on the chongmoja, the top part of the hat

1. Finishing and decorating work

1. Finishing and decorating work

2. Making the jeongte, or the rim of the hat

3. Attaching the jeongte to the cheongae

4. Attaching the cheongae into the onto the inside of the chongmoja with iron pins

5. Applying the black ink and lacquer to the top of the chongmoja

6. Attaching the bamboo threads in a cross-pattern

7. Covering the hat with a silk cloth

8. Attaching the motte, a decoration, to the edge of the top of the chongmoja

9. Attaching the jeonggot, the chin strap

10. Applying black ink and drying

3) Making the yangtae

3) Making the yangtae

1. The taujib jabgi

2. Trimming the edge of the yangtae

3. Applying a mixture of fish glue and ink to the yangtae

4. Form the teujib jabgi using an iron

5. Attach the cheoldae and the jimitdae

6. Nulli hapjang

7. Attaching the bamboo strands and covering it with a silk cloth

8. Attaching the geocheoldae

4) Assembling the gat

1. Attaching the chongmoja to the yangtae with an iron pin

2. Attaching the engak to the jimitdae

3. Attaching the ttamdae to the jimitdae and the dwisae to the eungak

4. Piercing holes for the chin strap in the jimitdae

5) Applying ink and lacquer, and attaching the jukyreong

1) Materials and supplies used in gat-making

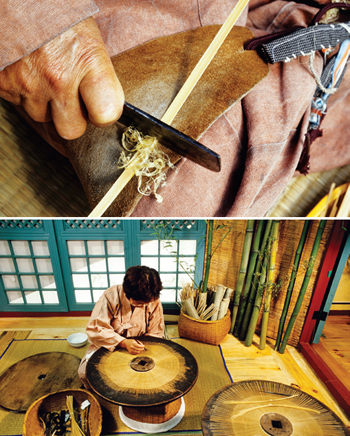

Preparation of the bamboo strips and strands

Bamboo culms are prepared to make various frames attached to the crown and brim of a gat, including the cheoldae, the geocheoldae, the jimitdae, the jeongte (also called the an-motte), the motte and the ttamdae. Bamboo strands are needed to make decorative supplies, such as the cheongae and the eungak. The process of preparing bamboo materials is called the geummok process.

Cheoldae refers to the outer frame attached to the brim of a gat. The process of making the frame is as follows: bamboo culms are cut with a knife into several slivers of a required size; two sides of a sliver are cut evenly after the sheaths are peeled off; one of the slivers is bent with a heated iron and the craftsman cuts off the upper side of the exterior, where the brim is attached with the knife, and the ends are tied together with a string. The jimitdae is the inner frame of the brim, made of a bamboo sliver and constructed in the same way as the cheoldae. The remaining bamboo slivers are trimmed to make geocheoldae, a frame added to the cheoldae, and the ttamdae, the thinly-sliced bamboo strip attached to the inner frame of the brim.

(Top, left) Bending the bamboo sliver with a heated iron to make the cheoldae, or outer frame

(Top, right) Cutting both sides of the outer frame evenly

(Bottom, left) Cutting off the upper side of the frame

(Bottom, right) Bending a bamboo sliver to make the jimitdae, the inner frame

5. The jimitdae

5. The jimitdae

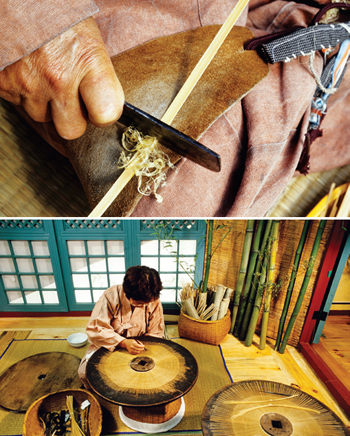

The cheongae and the eungak are accessories made with bamboo strands attached to the crown of the gat. The thickness of the strands depends on their purpose. The strands are produced by cutting and splitting one-joint culms of black bamboo. Then the bamboo strands are prepared: the bamboo culms are cut into even sticks and split into outer and inner bamboo slivers; the split outer slivers are boiled in hot water for about five hours and shredded with a knife to the appropriate size; several slivers are bundled together with a string and the tip of the bundle is sliced into a V shape; the bundle is placed on the knife fixed into the block stand and crushed by the thumb to separate the thin strands; finally, the strands are trimmed by rubbing them against the makers’ knees or with his hands.

(First row) Cutting a bamboo culm into slivers

(Second row, left) Cutting a bamboo culm into slivers; (right) Splitting bamboo sticks into outer and inner slivers

(Third row, left) Splitting the bamboo sticks into outer and inner slivers; (right) Outer and inner bamboo slivers

(Fourth row, left) Slicing the tip of a bundle of bamboo slivers; (right) Crushing the bamboo slivers into strands

(Bottom, center) A bundle of sliced bamboo slivers prepared to be made into strands

1.2 Making the eungak

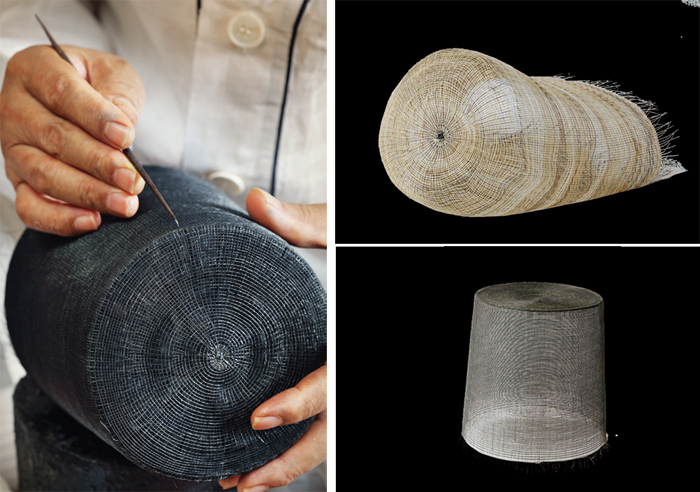

An eungak is a decorative accessory attached to the inside edge of the crown as a stiffener after the crown is joined to the brim. The product quality of a horsehair hat depends on the number of bamboo strands—from one to four strands—used for this accessory and the patterns—a diagonal cross pattern or a diagonal line pattern. The patterns made with bamboo strands are called the eungaksae.

An eungak is made as follows: an eungak block is hung on the block stand and the bamboo bands are glued onto the surface of the block; a long strip of bamboo is glued in a spiral on the block; the long strip is called an eungakseon; the eungaksae patterns are made by putting together the thin bamboo strands with fish glue and ironing; finally, a thin bamboo stick, the binetdae, is used to separate the finished eungak from the block. The bamboo accessory is dried on a shelf shaped like a grill basket, the beoreong, and it is coated with glue, to be cut out for use when needed.

(Top, left) Putting a long bamboo strip around the block to make the eungakseon

(Top, right) Putting the binetdae stick in between the eungak and the block, to separate the two

(Bottom, left) Making the eungak—gluing bamboo strands to make the engaksae patterns

(Bottom, right) A finished eungak

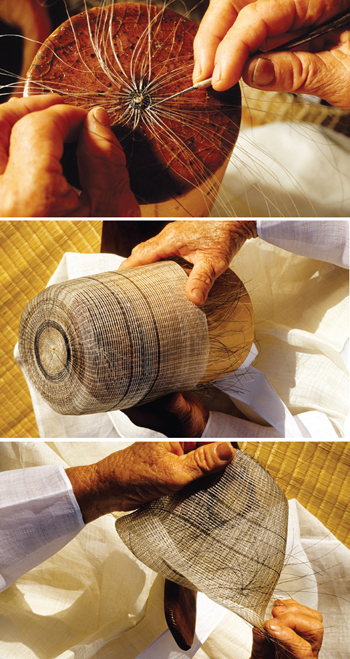

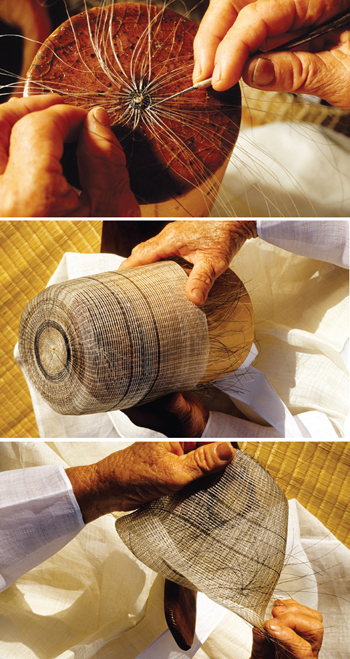

1.3 Making the cheongae

A cheongae is an accessory added to the inside of a horsehair or bamboo crown top as a decorative stiffener. It is made as follows: bamboo strands are placed in a grid shape on a small square frame; the grid of the strands are coated with fish glue and separated from the frame; a heated iron is used to attach it to the jeongte, the inner frame of the crown tip; finally, it is coated with black ink and dried on a shelf.

1.4 The golbaegi chongmoja hair-straightening process

The golbaegi process refers to the process of straightening the horsehair crown before attaching decorations and stiffeners. It is done as follows: a horsehair crown is placed on a hat block and a needle is used to evenly space the woven strands of its body; it is then boiled in hot water for about five hours and coated with thin fish glue; finally, it is dried for a day and separated from the block.

(Left) The golbaegi and momjul ttegi processes: spacing the weft strands evenly apart; (right) A picture of the top of a gat, before and after the golbaegi straightening and stiffening process

1.5 Making the jukdaewu crown

The jukdaewu is the bamboo crown made by putting together fine bamboo strands one by one. It can be used for all types of gat, ranging from those of the highest to the lowest quality. The highest-quality gat use crowns with three to four layers of bamboo strands, while inferior gat use crowns made by gluing strands in a diagonal cross shape, covered with a hemp cloth.

(Top) attaching the bamboo strands to the crown block; (bottom) the finished bamboo crowns

2) Finishing work on the chongmoja, the top part of the hat

This process is not required for the making of the bamboo crowns. It is carried out prior to joining the crown to the brim after the golbaegi straightening process is completed. Horsehair hats have different names depending on the materials attached to the crown during the finishing phase, such as the jinsarip, silk threads attached to the crown, the juksarip, bamboo threads attached to the crown, or the porip, when the hat is covered with silk or hemp cloth.

2.1 Finishing and decorating work

The process begins by decorating and stiffening the tip of the crown after the woven strands of the crown are evenly spaced. It is done as follows: a bamboo stick is prepared to make the inner frame of the crown tip; the stick is shredded into slivers and a heated iron is used to bend the slivers; the ends are tied together with a piece of silk cloth and heated to fix the circular shape; the bent sliver is split into thinner pieces and one end of a sliver is sliced to make the joint smooth; a frame is made to fit the inside of the crown tip; a pre-prepared cheondae is placed on the frame and is pressed into place with a heated iron; excess strands around the frame are trimmed off; the cheongae-attached frame is coated with black ink and glue and then left to dry on the beoreong; it is then glued to the inside of the crown and the crown is placed onto the block and the frame is fixed to the inside of the crown tip with the iron; the crown is coated with black ink and glue, then left to dry on the beoreong; two strands of bamboo are attached in a cross shape from the tip to the bottom of the crown, which divides the crown tip into four equal parts; finally, a thin frame, the motte, is attached to the outer edge of the crown tip, coated with glue and then left on the shelf to dry.

The process of covering the crown with silk or hemp cloth is as follows: water is sprayed evenly onto a sheet of raw silk fabric and the fabric is stuck onto the bottom half of the crown and attached to the surface of the crown by an iron; the process is repeated for the top half of the crown; the point on the crown body where the two pieces of cloth adjoin is pressed by iron; the remaining cloth is cut from the crown tip and ten from adjoining point, by pressing the knife while pulling the cloth; flue is applied to where the cloths adjoin; the crown is covered with another piece of raw silk fabric; one more piece of silk is stuck around eh crown tip; the silk-covered crown is left on the shelf to dry and trimmings are removed by knife and iron; finally, a motte is attached around the crown tip depending on the type of hat. Glue is applied and dried.

The jeonggot decoration is made of hanji, a traditional style of paper, and is attached on the inside of the crown tip.

After these decorations and finishing touches are completed, the finished crown is placed onto the hat block and the bottom circumference of the crown is measured to make an inner frame of the brim. The inner frame is coated with black ink and then dried.

*This series of article has been made possible through the cooperation of the National Research Institute of Cultural Heritage. (Source: Intangible Cultural Heritage of Korea)

3. The process and tools of making a gat

1) Materials and supplies used in gat-making

1. Preparation of the bamboo strips and strands

2. Making the eungak

3. Making the cheongae

4. The golbaegi chongmoja hair-straightening process

5. Making the jukdaewu crown

2) Finishing work on the chongmoja, the top part of the hat

2. Making the jeongte, or the rim of the hat

3. Attaching the jeongte to the cheongae

4. Attaching the cheongae into the onto the inside of the chongmoja with iron pins

5. Applying the black ink and lacquer to the top of the chongmoja

6. Attaching the bamboo threads in a cross-pattern

7. Covering the hat with a silk cloth

8. Attaching the motte, a decoration, to the edge of the top of the chongmoja

9. Attaching the jeonggot, the chin strap

10. Applying black ink and drying

1. The taujib jabgi

2. Trimming the edge of the yangtae

3. Applying a mixture of fish glue and ink to the yangtae

4. Form the teujib jabgi using an iron

5. Attach the cheoldae and the jimitdae

6. Nulli hapjang

7. Attaching the bamboo strands and covering it with a silk cloth

8. Attaching the geocheoldae

4) Assembling the gat

1. Attaching the chongmoja to the yangtae with an iron pin

2. Attaching the engak to the jimitdae

3. Attaching the ttamdae to the jimitdae and the dwisae to the eungak

4. Piercing holes for the chin strap in the jimitdae

5) Applying ink and lacquer, and attaching the jukyreong

1) Materials and supplies used in gat-making

Preparation of the bamboo strips and strands

Bamboo culms are prepared to make various frames attached to the crown and brim of a gat, including the cheoldae, the geocheoldae, the jimitdae, the jeongte (also called the an-motte), the motte and the ttamdae. Bamboo strands are needed to make decorative supplies, such as the cheongae and the eungak. The process of preparing bamboo materials is called the geummok process.

Cheoldae refers to the outer frame attached to the brim of a gat. The process of making the frame is as follows: bamboo culms are cut with a knife into several slivers of a required size; two sides of a sliver are cut evenly after the sheaths are peeled off; one of the slivers is bent with a heated iron and the craftsman cuts off the upper side of the exterior, where the brim is attached with the knife, and the ends are tied together with a string. The jimitdae is the inner frame of the brim, made of a bamboo sliver and constructed in the same way as the cheoldae. The remaining bamboo slivers are trimmed to make geocheoldae, a frame added to the cheoldae, and the ttamdae, the thinly-sliced bamboo strip attached to the inner frame of the brim.

(Top, left) Bending the bamboo sliver with a heated iron to make the cheoldae, or outer frame

(Top, right) Cutting both sides of the outer frame evenly

(Bottom, left) Cutting off the upper side of the frame

(Bottom, right) Bending a bamboo sliver to make the jimitdae, the inner frame

The cheongae and the eungak are accessories made with bamboo strands attached to the crown of the gat. The thickness of the strands depends on their purpose. The strands are produced by cutting and splitting one-joint culms of black bamboo. Then the bamboo strands are prepared: the bamboo culms are cut into even sticks and split into outer and inner bamboo slivers; the split outer slivers are boiled in hot water for about five hours and shredded with a knife to the appropriate size; several slivers are bundled together with a string and the tip of the bundle is sliced into a V shape; the bundle is placed on the knife fixed into the block stand and crushed by the thumb to separate the thin strands; finally, the strands are trimmed by rubbing them against the makers’ knees or with his hands.

(First row) Cutting a bamboo culm into slivers

(Second row, left) Cutting a bamboo culm into slivers; (right) Splitting bamboo sticks into outer and inner slivers

(Third row, left) Splitting the bamboo sticks into outer and inner slivers; (right) Outer and inner bamboo slivers

(Fourth row, left) Slicing the tip of a bundle of bamboo slivers; (right) Crushing the bamboo slivers into strands

(Bottom, center) A bundle of sliced bamboo slivers prepared to be made into strands

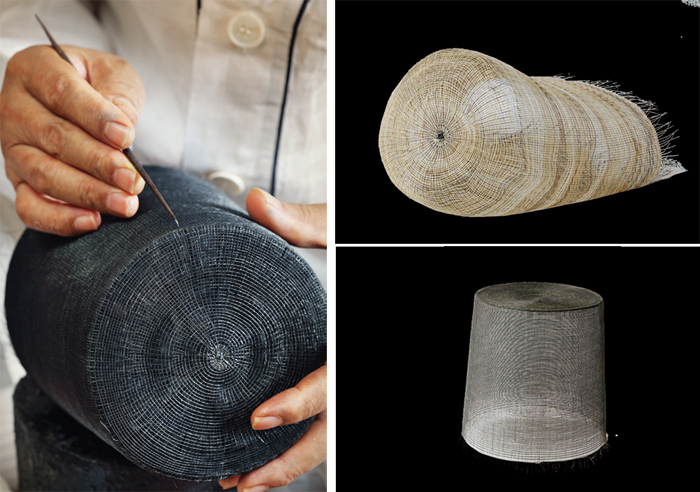

1.2 Making the eungak

An eungak is a decorative accessory attached to the inside edge of the crown as a stiffener after the crown is joined to the brim. The product quality of a horsehair hat depends on the number of bamboo strands—from one to four strands—used for this accessory and the patterns—a diagonal cross pattern or a diagonal line pattern. The patterns made with bamboo strands are called the eungaksae.

An eungak is made as follows: an eungak block is hung on the block stand and the bamboo bands are glued onto the surface of the block; a long strip of bamboo is glued in a spiral on the block; the long strip is called an eungakseon; the eungaksae patterns are made by putting together the thin bamboo strands with fish glue and ironing; finally, a thin bamboo stick, the binetdae, is used to separate the finished eungak from the block. The bamboo accessory is dried on a shelf shaped like a grill basket, the beoreong, and it is coated with glue, to be cut out for use when needed.

(Top, left) Putting a long bamboo strip around the block to make the eungakseon

(Top, right) Putting the binetdae stick in between the eungak and the block, to separate the two

(Bottom, left) Making the eungak—gluing bamboo strands to make the engaksae patterns

(Bottom, right) A finished eungak

1.3 Making the cheongae

A cheongae is an accessory added to the inside of a horsehair or bamboo crown top as a decorative stiffener. It is made as follows: bamboo strands are placed in a grid shape on a small square frame; the grid of the strands are coated with fish glue and separated from the frame; a heated iron is used to attach it to the jeongte, the inner frame of the crown tip; finally, it is coated with black ink and dried on a shelf.

1.4 The golbaegi chongmoja hair-straightening process

The golbaegi process refers to the process of straightening the horsehair crown before attaching decorations and stiffeners. It is done as follows: a horsehair crown is placed on a hat block and a needle is used to evenly space the woven strands of its body; it is then boiled in hot water for about five hours and coated with thin fish glue; finally, it is dried for a day and separated from the block.

(Left) The golbaegi and momjul ttegi processes: spacing the weft strands evenly apart; (right) A picture of the top of a gat, before and after the golbaegi straightening and stiffening process

1.5 Making the jukdaewu crown

The jukdaewu is the bamboo crown made by putting together fine bamboo strands one by one. It can be used for all types of gat, ranging from those of the highest to the lowest quality. The highest-quality gat use crowns with three to four layers of bamboo strands, while inferior gat use crowns made by gluing strands in a diagonal cross shape, covered with a hemp cloth.

(Top) attaching the bamboo strands to the crown block; (bottom) the finished bamboo crowns

2) Finishing work on the chongmoja, the top part of the hat

This process is not required for the making of the bamboo crowns. It is carried out prior to joining the crown to the brim after the golbaegi straightening process is completed. Horsehair hats have different names depending on the materials attached to the crown during the finishing phase, such as the jinsarip, silk threads attached to the crown, the juksarip, bamboo threads attached to the crown, or the porip, when the hat is covered with silk or hemp cloth.

2.1 Finishing and decorating work

The process begins by decorating and stiffening the tip of the crown after the woven strands of the crown are evenly spaced. It is done as follows: a bamboo stick is prepared to make the inner frame of the crown tip; the stick is shredded into slivers and a heated iron is used to bend the slivers; the ends are tied together with a piece of silk cloth and heated to fix the circular shape; the bent sliver is split into thinner pieces and one end of a sliver is sliced to make the joint smooth; a frame is made to fit the inside of the crown tip; a pre-prepared cheondae is placed on the frame and is pressed into place with a heated iron; excess strands around the frame are trimmed off; the cheongae-attached frame is coated with black ink and glue and then left to dry on the beoreong; it is then glued to the inside of the crown and the crown is placed onto the block and the frame is fixed to the inside of the crown tip with the iron; the crown is coated with black ink and glue, then left to dry on the beoreong; two strands of bamboo are attached in a cross shape from the tip to the bottom of the crown, which divides the crown tip into four equal parts; finally, a thin frame, the motte, is attached to the outer edge of the crown tip, coated with glue and then left on the shelf to dry.

The process of covering the crown with silk or hemp cloth is as follows: water is sprayed evenly onto a sheet of raw silk fabric and the fabric is stuck onto the bottom half of the crown and attached to the surface of the crown by an iron; the process is repeated for the top half of the crown; the point on the crown body where the two pieces of cloth adjoin is pressed by iron; the remaining cloth is cut from the crown tip and ten from adjoining point, by pressing the knife while pulling the cloth; flue is applied to where the cloths adjoin; the crown is covered with another piece of raw silk fabric; one more piece of silk is stuck around eh crown tip; the silk-covered crown is left on the shelf to dry and trimmings are removed by knife and iron; finally, a motte is attached around the crown tip depending on the type of hat. Glue is applied and dried.

The jeonggot decoration is made of hanji, a traditional style of paper, and is attached on the inside of the crown tip.

After these decorations and finishing touches are completed, the finished crown is placed onto the hat block and the bottom circumference of the crown is measured to make an inner frame of the brim. The inner frame is coated with black ink and then dried.

*This series of article has been made possible through the cooperation of the National Research Institute of Cultural Heritage. (Source: Intangible Cultural Heritage of Korea)

![Gat, traditional headgear in Korea [3]](/upload/content/image/1392095636707.jpg)

![Gat, traditional headgear in Korea [2]](/upload/content/image/1391590339998.jpg)