View this article in another language

- 한국어

- English

- 日本語

- 中文

- العربية

- Español

- Français

- Deutsch

- Pусский

- Tiếng Việt

- Indonesian

This is the seventh part in our series, “Onggi, traditional earthenware vessel in Korea.”

Remove the Onggi from the kiln

After the firing is finished for the kiln and the potteries to cool off while the kiln is sealed. This is because the potteries, if exposed to the outside air suddenly after baking at high temperature, may crack. It is much easier to move the potteries out of the kiln after firing, than moving them inside before. Because the finished potteries have been hardened, and so they cannot be cracked or damaged easily.

1. A broken Onggi comes out from the kiln due to a high temperature.

2. Take down the kiln entrance to remove the Onggi.

3. Collect the Onggi with Onggijang's heart.

4. Separate the stuck Onggi from the molten glaze.

5. The finished product is easy to move.

6. The finished product is easy to move.

7. The Onggijang (potter) looks at the completed Onggi

Firing of the Unglazed Jilgeureut

Unglazed pottery is called, 'Jilgeureut,' after completing firing process. That is why, firing of the unglazed pottery should be treated differently from glazed pottery or porcelain.

From the beginning, stacking the raw potteries in the kiln is different. The potteries are stacked upside down and diagonally so the smoke can permeate into it. And the kiln temperature is from 800℃ to 1110℃ because there is no need to melt the glaze. Also firing takes only two days to complete.

1. The raw Jilgeureut are stacked diagonally in order for the smoke to permeate into them.

2. Jilgeureut is being stacked in front of the kiln for baking.

3. The Jigeureut need to be level with their bottom supported because the kiln is slanted.

4. The Onggijang takes the Onggi into the kiln.

5. Supporting the bottom of a Jilgeureut to make it level.

6, 7. The raw Jilgeureut are staked diagonally in order for the smoke to permeate into them.

8. Firing the kiln for baking the Jilgeureut.

9. The kiln temperature for the unglazed Jilgeureut can be increased fast because of the small size.

10. Stack the fine logs at the side of the entrance to prevent the heat disappearance at the side of the kiln.

11. Lots of firing woods are fed into the kiln at once, in order for the unglazed Jilgeureut to soak lots of smoke while being fired.

12. The Onggijang looks at the status of the Jilgeureut through the entrance of the kiln.

13. The Onggijang gets the charcoal stacked at the front of the kiln.

14. Get out the charcoal then put the fine longs into the kiln.

15. Making smoke for covering the Jilgeureut.

16. The Onggijang prepares clay and grass roots for blocking the entrance of the kiln.

17. When the firing is finished, block the entrance and the chimney to stop the escaping smoke.

18. The kiln should be sealed off completely, not allowing even a small opening because lack of smoke in the kiln will make a lighter colored product, which will lower the quality of the merchandize.

*This series of article has been made possible through the cooperation of the National Research Institute of Cultural Heritage. (Source: Intangible Cultural Heritage of Korea)

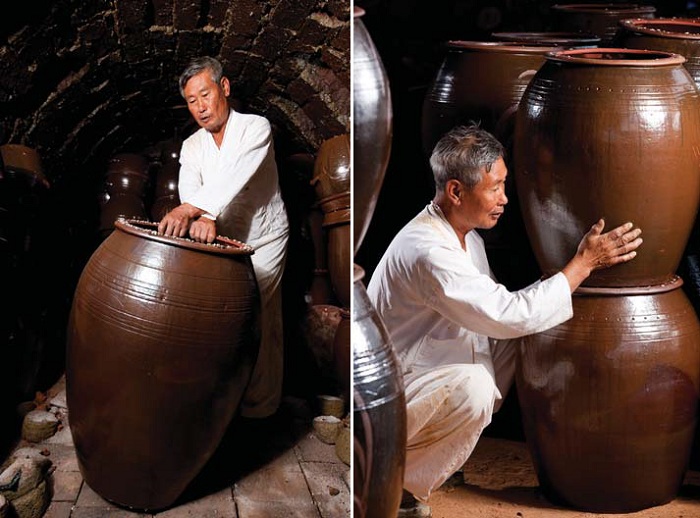

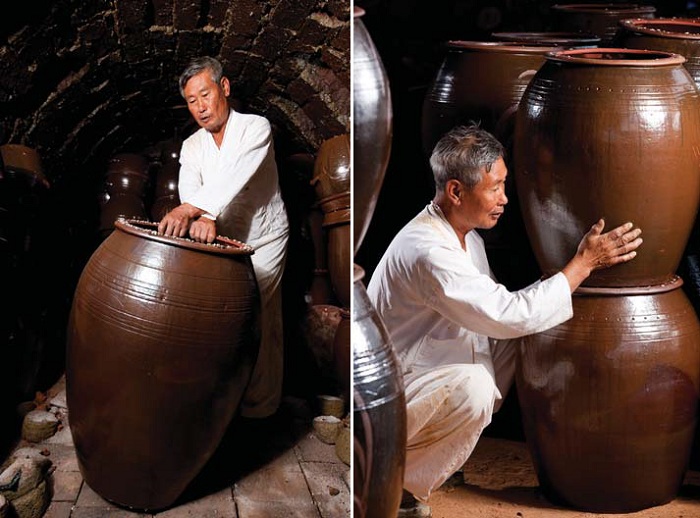

Remove the Onggi from the kiln

After the firing is finished for the kiln and the potteries to cool off while the kiln is sealed. This is because the potteries, if exposed to the outside air suddenly after baking at high temperature, may crack. It is much easier to move the potteries out of the kiln after firing, than moving them inside before. Because the finished potteries have been hardened, and so they cannot be cracked or damaged easily.

1. A broken Onggi comes out from the kiln due to a high temperature.

2. Take down the kiln entrance to remove the Onggi.

3. Collect the Onggi with Onggijang's heart.

4. Separate the stuck Onggi from the molten glaze.

5. The finished product is easy to move.

6. The finished product is easy to move.

7. The Onggijang (potter) looks at the completed Onggi

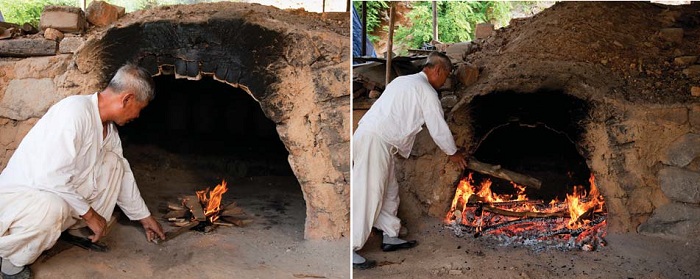

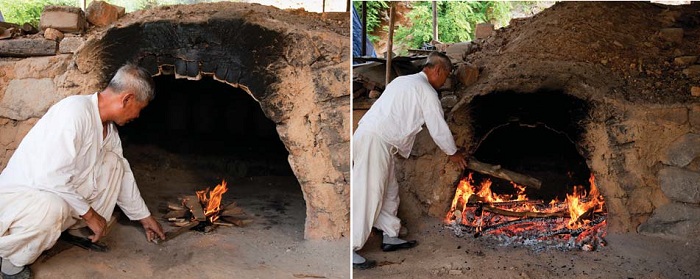

Firing of the Unglazed Jilgeureut

Unglazed pottery is called, 'Jilgeureut,' after completing firing process. That is why, firing of the unglazed pottery should be treated differently from glazed pottery or porcelain.

From the beginning, stacking the raw potteries in the kiln is different. The potteries are stacked upside down and diagonally so the smoke can permeate into it. And the kiln temperature is from 800℃ to 1110℃ because there is no need to melt the glaze. Also firing takes only two days to complete.

1. The raw Jilgeureut are stacked diagonally in order for the smoke to permeate into them.

2. Jilgeureut is being stacked in front of the kiln for baking.

3. The Jigeureut need to be level with their bottom supported because the kiln is slanted.

4. The Onggijang takes the Onggi into the kiln.

5. Supporting the bottom of a Jilgeureut to make it level.

6, 7. The raw Jilgeureut are staked diagonally in order for the smoke to permeate into them.

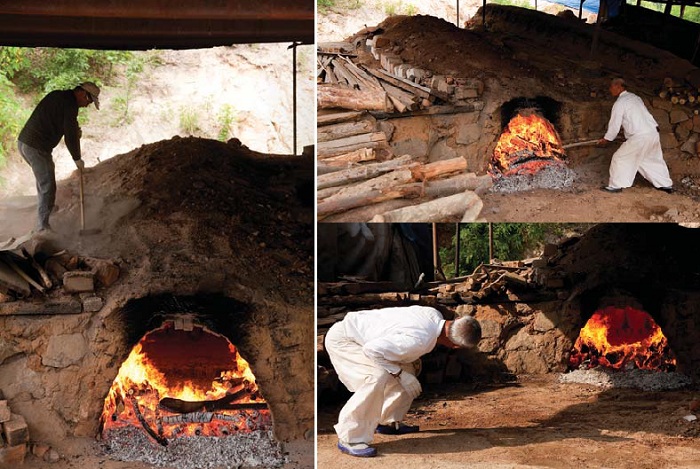

8. Firing the kiln for baking the Jilgeureut.

9. The kiln temperature for the unglazed Jilgeureut can be increased fast because of the small size.

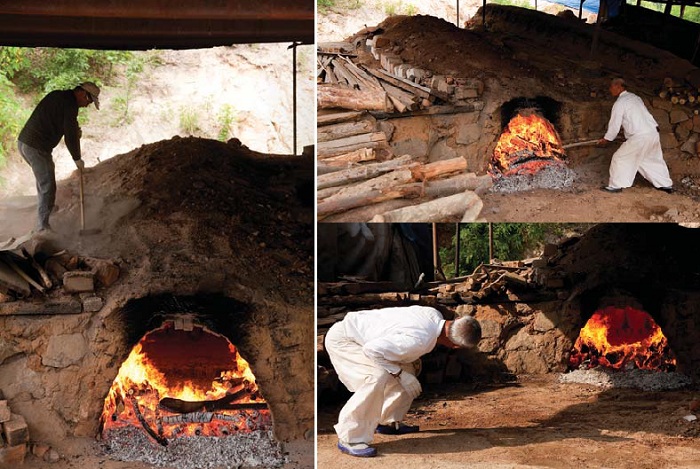

10. Stack the fine logs at the side of the entrance to prevent the heat disappearance at the side of the kiln.

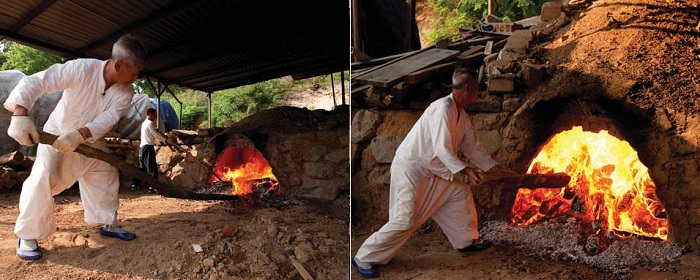

11. Lots of firing woods are fed into the kiln at once, in order for the unglazed Jilgeureut to soak lots of smoke while being fired.

12. The Onggijang looks at the status of the Jilgeureut through the entrance of the kiln.

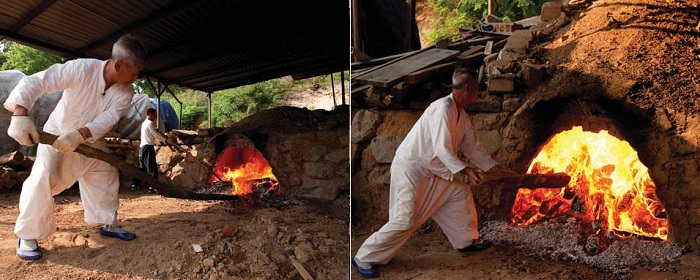

13. The Onggijang gets the charcoal stacked at the front of the kiln.

14. Get out the charcoal then put the fine longs into the kiln.

15. Making smoke for covering the Jilgeureut.

16. The Onggijang prepares clay and grass roots for blocking the entrance of the kiln.

17. When the firing is finished, block the entrance and the chimney to stop the escaping smoke.

18. The kiln should be sealed off completely, not allowing even a small opening because lack of smoke in the kiln will make a lighter colored product, which will lower the quality of the merchandize.

*This series of article has been made possible through the cooperation of the National Research Institute of Cultural Heritage. (Source: Intangible Cultural Heritage of Korea)