-

Korea.net's 24-hour YouTube channel

Korea.net's 24-hour YouTube channel- NEWS FOCUS

- ABOUT KOREA

- EVENTS

- RESOURCES

- GOVERNMENT

- ABOUT US

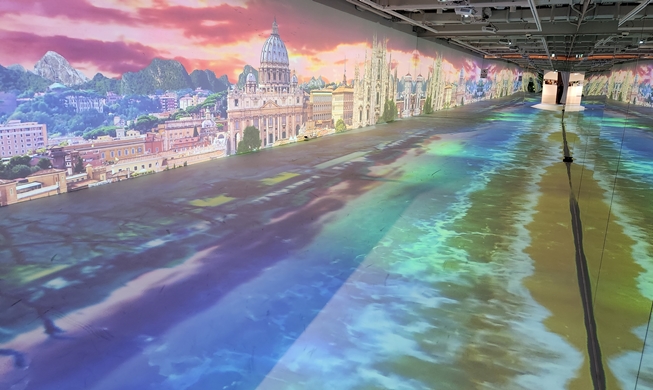

DORCO showcases a variety of its razor blades, including disposable razors (right) through to the world’s first seven-blade razors (left).

The world has been captured by the disposable razors, the women’s six-blade razors and even by the seven-blade razors of a certain company. Its customers are located in Europe, the Americas, Asia, the Middle East and Africa.

This is DORCO, a blade company which marks its 60th anniversary this year.

DORCO was founded in 1955 as Dong Yang Light Metal Inc. In 1962, the company began producing razor blades. In 1990, the firm changed its name to “DORCO,” a combination of “DO,” from its former name, “R” for razor, and “CO” for company.

DORCO has been producing double-edged razors since 1970. This is one of the oldest products of the firm.

At the end of 2014, DORCO developed the world's first seven-bladed razor, the Pace7.

In the razor blade industry, DORCO has some of the world’s sharpest technology. The company has been leading the world market by developing the world’s first six-blade razor, the PACE6, in 2006, and then the seven-blade razor, the PACE7, at the end of this year.

DORCO’s technological prowess has been recognized by customers both domestic and international. The company has been recording sales growth of higher than 15 percent every year over recent years. Last year, its annual sales hit approximately KRW 225.6 billion. Its overseas sales, in particular, accounted for more than 70 percent of those total sales. Ever since it began exporting in 1976, the company has been attracting customers in about 130 countries around the globe. The company has received favorable responses from overseas customers, especially in Europe, the Middle East and Africa, as DORCO has focused on research and development (R&D) that takes into consideration the characteristics of human hair across the races.

CEO Baek Hakgi says, 'Nanometer-level supreme precision technology and the hardness of steel enable users to enjoy a good shave, leaving a clean finish with less damage to the skin.' He emphasizes DORCO’s world-leading razor blade technology.

Korea.net met with CEO Baek Hakgi of DORCO to talk about his company's history and goals and future plans for the company.

- DORCO began its business in the 1950s, even before the scars of war were healed. Tell us more about what it was like to produce razor blade at that time.

When DORCO began in 1955 as Dong Yang Light Metal Inc., it started making zippers and kitchen knives. When the razors that the U.S. soldiers used were flown to Korea after the Korean War (1950-1953), however, we thought about producing razors for ourselves and began the business in 1962.

- DORCO has a 60-year history. What do you think is the secret of longevity for the company?

The key to a long history lies in rewarding customers’ trust in us with honesty and with the best high-quality products. Honesty and trust are the two main values which lie at the core of the company’s history. For example, before DORCO began producing razors, its former CEO ran a rice-trading business. During war, when everyone was a refugee and there were no banking services, the former DORCO CEO and founder carried around a big bag of cash in order to deal with his suppliers, as he felt that keeping good credit and honesty were the top priorities.

- DORCO developed a six-blade razor in 2006, and a seven-blade razor in 2014, each of them the first of its kind in the world. Were there any difficulties in the R&D procedures? If yes, how did you overcome them?

Being able to develop such razors is the result of our R&D efforts. We thought about how to make good products with such good steel. Some other companies produce similar razor products by welding the center of the razor blades, which requires high costs and involves a complicated production method.

DORCO, however, developed the world’s first technology to bend a strong razor blade directly. This technology involves fewer costs and a more simple production process. This technology enabled us to put more razor blades, up to seven, on our blades, allowing users to have a good shave with a safer, cleaner and softer finish.

In fact, in the late 1980s, we faced hardship and lost competitiveness as overseas companies entered the Korean market due to the market being opened. DORCO focused on R&D with the determined goal of making the best quality product in the world. With this in mind, we built a research center in 1997. Up until today, we have been investing more than 15 percent of our total annual sales into R&D. Our overseas competitors have been strictly protecting their technology. As razor blade technology is a very specific field, there are limits to what kind of joint research we can undertake with domestic research institutions. So we had to do all our R&D ourselves, with our own technological knowhow. Over more than 10 years of R&D, we experienced a lot of trial and error. However, we now successfully own our own technology, and have developed the core technologies of other companies by ourselves.

We did experience difficulties, as our R&D efforts did not bring instant results. However, we made it, thanks to passionate challenges and to the full support of the board of executives. Personally, it has been very rewarding for me, too.

- What was the most critical factor when developing DORCO’s proprietary technology to develop special razor blades?

We focused a lot of energy on developing good razor blades that can differentiate us from other firms. Think of a warrior's fine blade in the movies. Such excellent blades are made through a process of pounding for a long time. Unlike other companies that make razor blades through stropping, we make razor blades by pounding stainless steel. This technology is owned by only two companies in the world, and one of them is us. When we shave with such razor, we can have a cleaner cut shave with less irritation to the skin. This is because the pounding process makes the longevity of razor blades longer, as it makes the steel much stronger with a denser structure.

CEO Baek says with a smile that, 'DORCO is the world’s top razor blade company. We recommend people replace their razor cartridge twice a month, but our products last a long time, which makes me concerned.'

- Are there any particular products especially loved by certain regions or countries?

Razors with three or more blades enjoy high popularity among customers in Europe, the U.S. and Australia. In the Middle East and Central and South America, double-sided and disposable razors are so popular that more than 120 million units are sold every month. Double-sided razors are also popular in Asia, the Middle East and Africa.

To be honest, we cannot supply all of our customers' needs as we lack production facilities. Currently, we have six factories, including two in Korea. We plan to build more plants in Korea and Vietnam this year.

- Customers are very smart and compare many similar products these days. What is the most important value for DORCO when making its products?

Our basic philosophy is to make the world’s top quality product by honestly realizing the value of the product. We also pursue the best designs and aim for convenience. The goal of DORCO is to make products that realize the practical value of the products in an honest manner so that people can keep it for a long time, like a luxury good.

- Compared with your competitors, let’s say, Gillette or Schick, what are some of DORCO's strengths?

DORCO’s strengths lie in our top quality razor blades. It is important to make razor blades that are strong and good to cut human hair with, leaving less damage to the skin. It also has to maintain a clean shave for a long time.

The knowhow to make razor blades lies in its strength and nanometer-level precision technology. Human hairs are as strong and tough as copper wire of the same thickness. When wet, its strength changes as that of aluminum. DORCO’s razor blades have a minute sawtooth structure. When it meets human hairs, it cuts the hair clean, but gives less irritation to the skin, leaving a clean finish. Also, we coated the surface of the razor blade with a very thin, diamond-like layer to enhance its strength and to upgrade its precision.

- What are DORCO’s future plans?

DORCO is the No. 2 firm in the private label market in Europe and the U.S., and our products are sold at Carrefour and Auchan in France and at Sam’s Club and Costco in the U.S. Many overseas buyers come to us for business. In the future, we wish to upgrade our brand image overseas. We wish to focus on strengthening our marketing online and in emerging markets, too.

Article by Yoon Sojung

Photos: Jeon Han

Korea.net Staff Writers

arete@korea.kr

Most popular

- First hearing-impaired K-pop act hopes for 'barrier-free world'

- 'Mad Max' director impressed by 'cinema-literate' Korean viewers

- Romanian presidential couple visits national cemetery

- 'Korean mythology is just as wonderful as Greek and Roman'

- Hit drama 'Beef' wins awards from 3 major Hollywood guilds